Development project "Hydra"

"Hydra" is Nordlaks' next major development project. In 2025, the semi-closed production tank will be in place at the Sørvika location in Hadsel municipality.

Facts about the "Hydra" project

In February 2021, Nordlaks took over a company called Hydra Salmon Company II AS. Prior to the takeover, the company had been given four development permits for the development of the “production tank” concept. This means that Nordlaks has now taken over the development project and is working to realize the production tank in line with the commitment from the Directorate of Fisheries.

Nordlaks considers that the technology in the project is an important contribution to the further development of Nordlaks and to the technological diversity in the aquaculture industry. By realizing the Hydra project, Nordlaks will develop expertise in the design and operation of semi-closed concepts as well, with expected benefits both in terms of escape and biosecurity, particularly against salmon lice.

“The idea behind the concept is to utilize the comparative advantages for salmon farming that you have in Norway, and at the same time to use technical solutions to address environmental challenges such as salmon lice. This is also a good solution from a sustainability and fish welfare perspective. When we take over this development project, Nordlaks is simultaneously embarking on a new and interesting development track.”

– CEO Eirik Welde

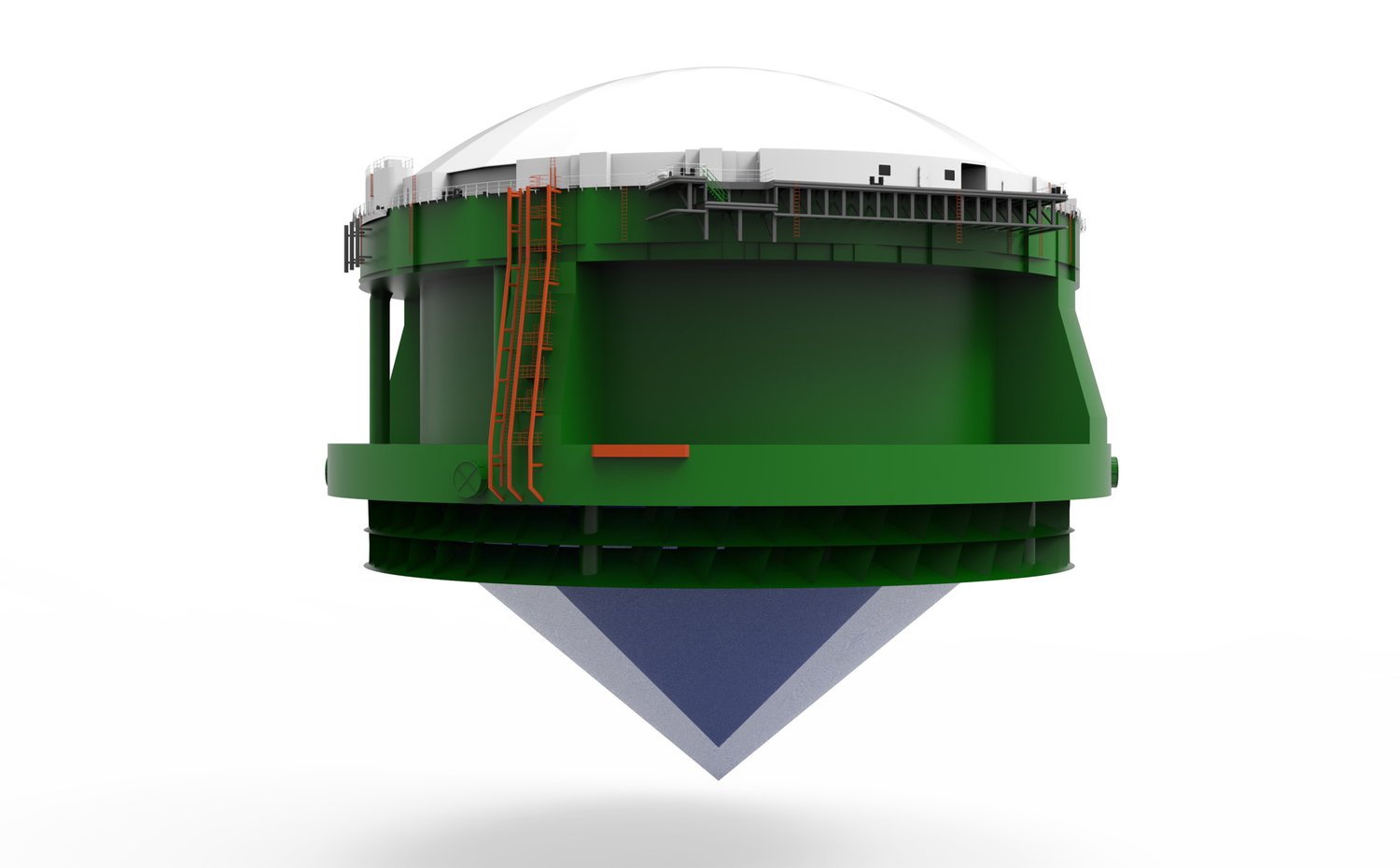

About the construction

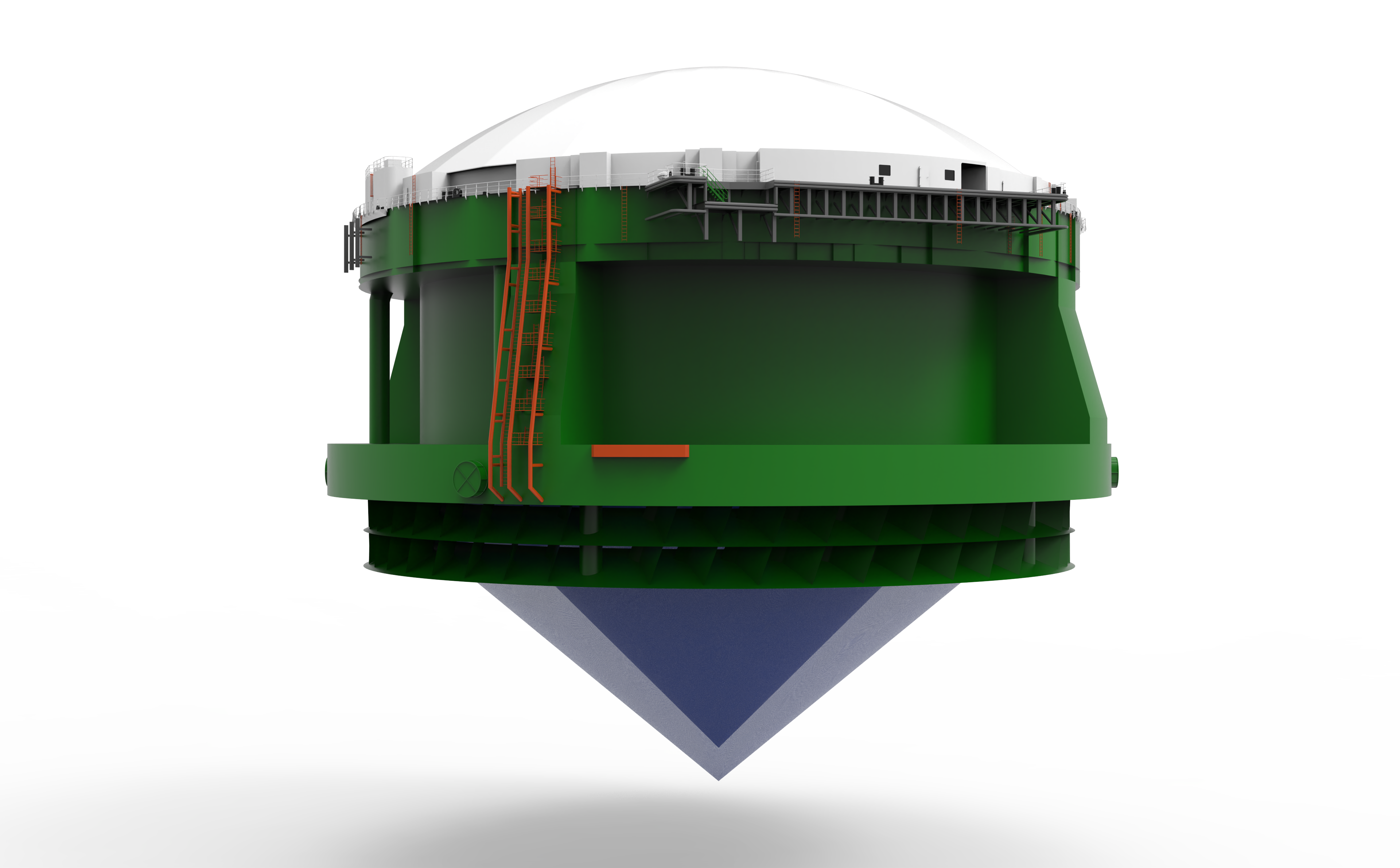

The “production tank” is made for breeding Atlantic salmon or rainbow trout. The unit has weather sealed roof and walls down to 20 meters below sea level. This construction is intended to prevent salmon lice and disease transmission from entering the fish. At the bottom of the sealed wall, there will be a system for replacing and energizing the water inside the tank. The production tank will have integrated systems for feeding and handling dead fish. The unit will not be permanently operated. External assistance may be necessary when receiving feed, equipment, removing fish, emptying silage and more. The production tank does not depend on the feed raft. It will be connected to shore power, but will have backup diesel generators in the event of a power outage.

The unit consists of three parts: surface module, tank / hull wall and guide vane module.

Surface module

The surface module consists of a circular hull and a roof section shaped like a dome. The hull itself (upper barrel module, hull wall and guide vane module) must be made of steel, while the roof section must be made of a lighter material. The module is tight with the exception of exhaust / intake air. The hull will have an inner diameter of 60 meters and an outer diameter of 72 meters. The surface module contains feed storage, machine room, workshop, dead fish system and more.

Tank- / Hull wall

The dense hull wall extends from the surface module and down to 20 meters below the water surface. The hull wall should act as a physical barrier to reduce the impact on the fish from the surroundings.

Guide vane module

This is a rigid construction consisting of a system of “wings” and shovels that follow the entire lower edge of the tank wall. The module will send water up and out to the sides of the production tank for powering and water replacement inside the tank.

Operation of the production tank

The production tank is designed for a maximum permitted biomass of 3120 tonnes (four development permits).

It must be possible to operate the production tank without permanent staffing, in the same way as traditional fish farms. The unit will not be dependent on feed fleet and will be operated with power supply from land. Some operations are expected to be able to be controlled remotely, such as opening hatches in connection with feed reception, camera surveillance of fish and facilities and feeding of fish. The unit is cleaned with a remote-controlled underwater vehicle (ROV) during production and between production cycles. The production tank is equipped with two docks (quay facilities) for mooring and mooring of passenger transport, service vessels or other support vessels.

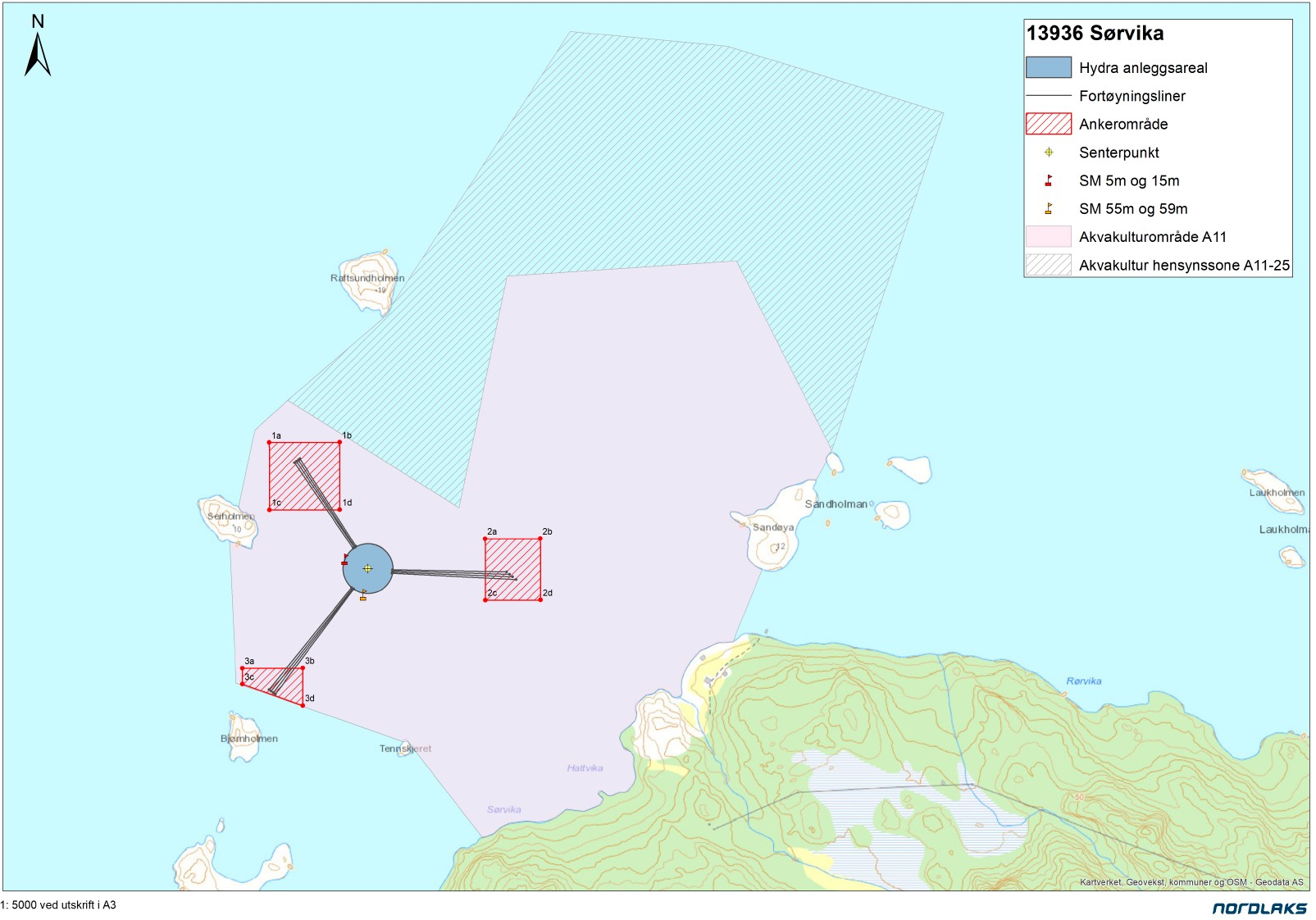

Location

Nordlaks has applied for a change of location in Sørvika in Hadsel municipality for testing Hydra. The location is at the northern end of Raftsundet, and with its current strength is well suited for testing the concept.

The application means that the current facility, with a surface area of approximately 25,000 square metres, will be removed and replaced with Hydra. Hydra has a surface area of approximately 5,000 square meters. This means that traffic and fishing prohibition zones on the site will be significantly smaller. Hydra has a different design to traditional fish farming facilities. The closed roof structure in particular means that the facility is higher and thus more visible in the landscape than traditional cages.

Knowledge sharing from the project

The commitment on development permits for the production tank specifies criteria for sharing knowledge from the project. In order to meet these criteria, Nordlaks shares experiences, new knowledge and data from the project in various ways. Some of the knowledge sharing takes place via publications that are available on this page.

Below you will find fact sheets about the Hydra project, and a report from the model test of the Hydra tank. The fact sheet includes information about the concept, participants and the project’s philosophy related to important aspects such as safety, operations, environment and fish health. The report documents fulfillment of target criterion 2.1 in commitments on development permits.

Hydra under water. Illustration: Nordlaks/NSK Ship Design.

Map section showing the requested location of Hydra at the location Sørvika in Hadsel. Illustration: From the application